When you’re building a custom apparel brand, print quality isn’t just about how something looks on day one — it’s about how it holds up after months of wear. Cracking, fading, and peeling can quickly turn a great design into a bad customer experience.

That’s why durability matters. And it’s also why DTF (Direct-to-Film) printing has become a go-to solution for modern brands that need flexibility, consistency, and long-lasting results.

How long do DTF prints actually last? Let’s break it down — from real-world lifespan to best care practices.

What Is DTF Printing?

DTF, or Direct-to-Film printing, is a process where a design is printed onto a specialized film, coated with adhesive powder, and then heat-pressed onto a garment. Unlike traditional printing methods, DTF:

- Requires no garment pretreatment

- Works across cotton, polyester, and blends

- Produces vibrant, opaque prints on light and dark fabrics

At Apliiq, we use production-grade DTF transfers designed specifically for apparel brands that expect professional-quality results at scale. You can learn more about our process here:

How Long Do DTF Prints Last?

When produced and applied correctly, high-quality DTF prints can last 50 to 100+ washes. If you are wearing a garment once per week, call it a “steady favorite.” That would be 1-2 years of use.

That kind of longevity puts DTF well ahead of many digital print options and makes it a strong choice for print-on-demand brands, limited drops, and everyday retail apparel.

The key is quality. Not all DTF prints are created equal — and the difference shows over time.

What Affects the Lifespan of DTF Prints?

Transfer Quality

Durability starts with the transfer itself. Ink formulation, adhesive powder quality, and film consistency all play a critical role. Professional-grade DTF transfers maintain flexibility while resisting cracking and edge lifting.

Application Process

DTF requires precise heat, pressure, and dwell time. When applied using calibrated equipment and consistent processes, the result is a strong bond that holds up through repeated wear and washing.

Improper application is one of the most common causes of early failure — including wrinkling, lifting, or uneven adhesion. If this happens, this guide can help:

Fabric Choice

DTF performs exceptionally well across a wide range of garments, especially cotton-poly blends where other methods struggle. Smooth, stable fabrics typically produce the longest-lasting results.

DTF vs Other Printing Methods: Durability Comparison

Different customization methods serve different needs. Here’s how they compare when longevity is the priority:

- DTF Printing: 50–100+ washes, excellent flexibility, ideal for full-color and detailed designs

- DTG Printing: 30–50 washes, very soft feel, best on 100% cotton

- Screen Printing: 100+ washes, ideal for bulk orders and simple graphics

- Embroidery: 100+ washes, premium texture, and dimension

DTF stands out for brands that want high-detail designs without large minimums or setup costs.

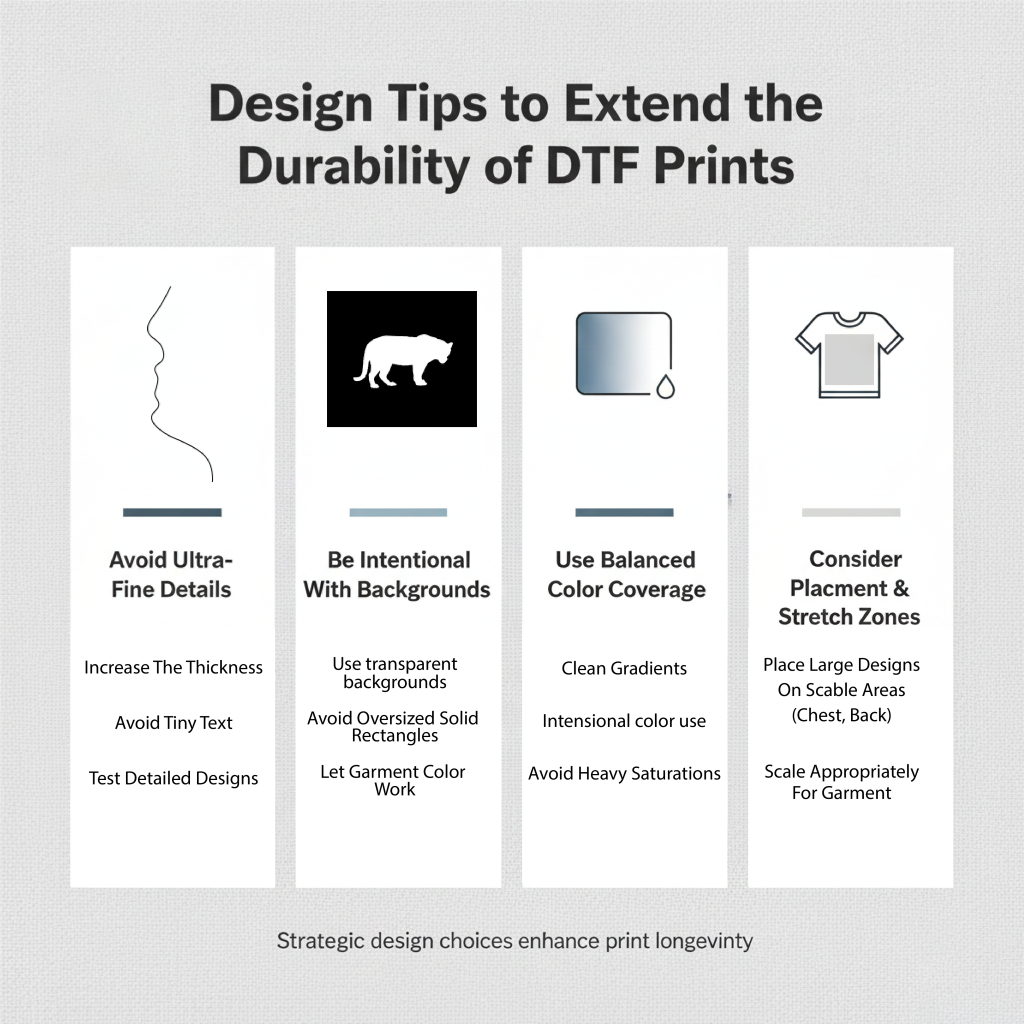

Design Tips to Extend the Durability of DTF Prints

Great durability isn’t just about production — design choices matter too. Here are proven design best practices to help DTF prints last longer:

Avoid Ultra-Fine Details

Extremely thin lines, micro-text, or hairline details are more prone to wear over time. Whenever possible:

- Increase line thickness slightly

- Avoid tiny text below legibility thresholds

- Test detailed designs before full release

Be Intentional With Backgrounds

Large solid backgrounds can increase ink density and stiffness. For better longevity:

- Use transparent backgrounds when possible

- Avoid oversized solid rectangles unless necessary

- Let the garment color work as part of the design

Use Balanced Color Coverage

DTF handles full color well, but overly heavy ink saturation can reduce flexibility. Clean gradients and intentional color use help prints move naturally with the fabric.

Consider Placement & Stretch Zones

Areas with heavy stretch (like side seams or ribbed cuffs) experience more stress. For best results:

- Place large designs on stable areas (chest, back, thigh, sleeve Etc.)

- Scale artwork appropriately for the garment type

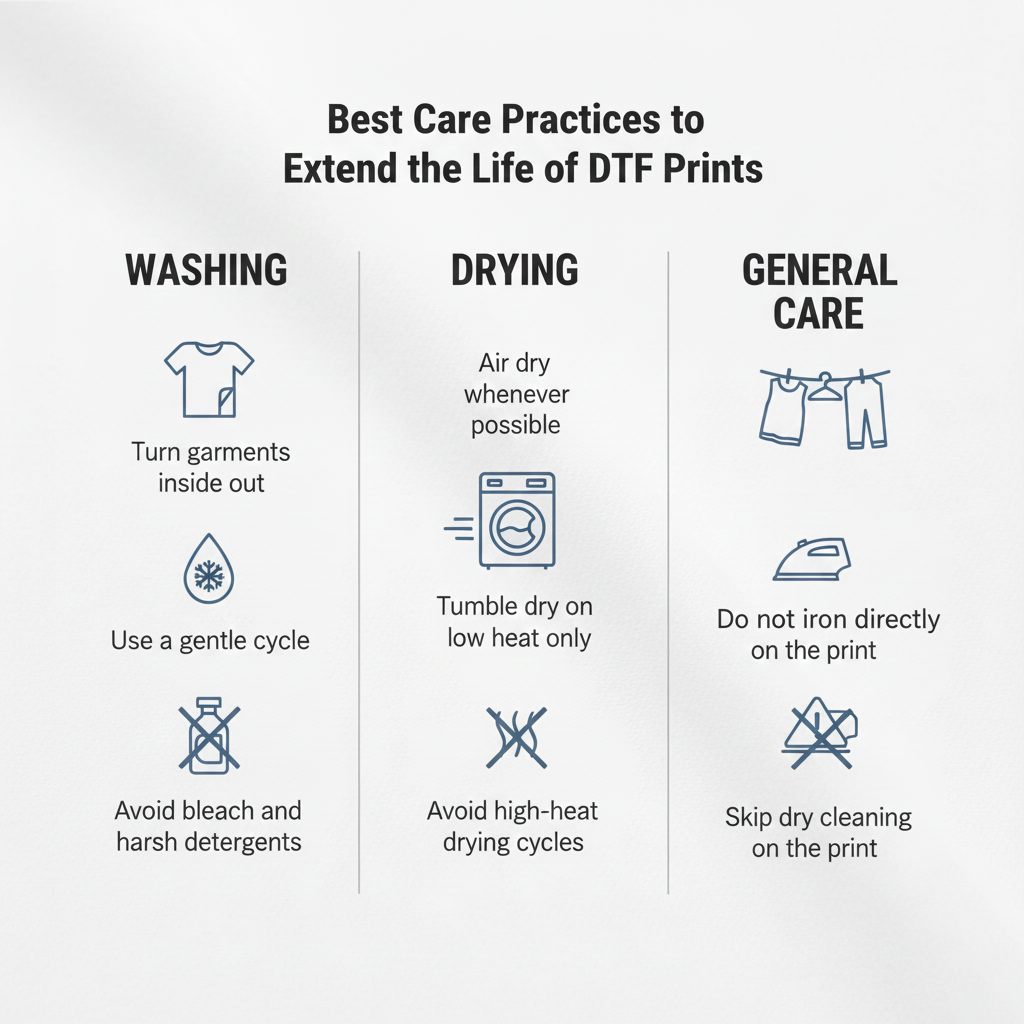

Best Care Practices to Extend the Life of DTF Prints

Even the most durable prints benefit from proper care. To help customers get the longest life from their garments, recommend the following:

Washing

- Turn garments inside out

- Wash in cold water

- Use a gentle cycle

- Avoid bleach and harsh detergents

Drying

- Air dry whenever possible

- Tumble dry on low heat only

- Avoid high-heat drying cycles

General Care

- Do not iron directly on the print

- Skip dry cleaning

These simple steps can significantly extend the life of a DTF print and keep it looking sharp.

DTF Transfers Are Built to Last

At Apliiq, DTF isn’t treated as a shortcut — it’s a production-ready solution built for real brands.

Our DTF process focuses on:

- Commercial-grade inks and adhesives

- Consistent color accuracy

- Flexible prints that move with the fabric

- Reliable durability for print-on-demand fulfillment

If you’re exploring DTF for your brand, learn more about our DTF transfers on demand and how they support scalable customization workflows:

Who Is DTF Printing Best For?

DTF printing is an ideal fit for:

- Apparel startups and emerging brands

- Print-on-demand sellers

- Multi-color logos and detailed artwork

- Small batch drops and online merch stores

It offers creative freedom without the constraints of traditional production minimums.

Common DTF Printing FAQs

Does DTF printing crack or peel over time?

When produced and applied correctly, high-quality DTF prints remain flexible and durable. Professional-grade DTF transfers are designed to move with the fabric, helping prevent cracking, peeling, or lifting through repeated wear and washes.

How long do DTF prints last?

With proper application and care, DTF prints can last 50–100+ washes, making them a reliable option for everyday apparel and print-on-demand products.

Does DTF feel heavy on garments?

Not at all. Modern DTF printing creates a lightweight, smooth finish that feels comfortable against the skin. The print flexes naturally with the garment without adding stiffness.

Is DTF printing good for dark garments?

Yes. DTF performs exceptionally well on dark fabrics. Because the ink sits on top of the garment, colors stay vibrant and opaque—even on black or deep-colored materials.

Can DTF be used on blended fabrics?

Absolutely. DTF works consistently on cotton, polyester, and cotton-poly blends, making it one of the most versatile apparel printing methods available.

Does DTF fade after washing?

High-quality DTF prints maintain color vibrancy when washed properly. Following recommended care instructions—cold wash and low heat drying—helps preserve the print long-term.

Is DTF better than DTG printing?

DTF and DTG serve different needs. DTF generally offers better durability on blends and dark garments, while DTG is best for soft, water-based prints on 100% cotton. Explore more here.

How does DTF compare to screen printing?

DTF offers more flexibility for full-color designs and small runs, while screen printing is ideal for large bulk orders with simple graphics. DTF eliminates setup costs and minimums.

Can DTF handle detailed or multi-color designs?

Yes. DTF excels at detailed artwork, gradients, and complex color designs, making it ideal for logos, illustrations, and photo-style graphics.

Is DTF suitable for print-on-demand brands?

Definitely, DTF is well-suited for print-on-demand because it supports small batch production, fast turnaround, and consistent quality without inventory risk.

Will DTF prints stretch with the fabric?

Yes. When applied correctly, DTF prints remain flexible and stretch with the garment, helping maintain comfort and durability during wear.

Can DTF be used on different apparel types?

DTF works across a wide range of products, including t-shirts, hoodies, sweatshirts, tote bags, and more—making it a versatile option for custom apparel collections.

Is DTF a good choice for growing apparel brands?

Yes. DTF offers scalability, consistent quality, and creative freedom, making it an excellent choice for brands launching new designs or expanding their product lines.

Final Thoughts

So, how long do DTF prints last? When done right — a long time.

With professional production, thoughtful design, proper application, and simple care practices, DTF printing delivers durability that modern apparel brands can rely on. It’s one of the most versatile customization methods available and a strong choice for brands that value quality, flexibility, and consistency.

At Apliiq, we help brands bring designs to life with printing methods built to last — so your customers keep coming back for more.